When I pulled the bottom cover off the clutch housing a pool of engine oil came out. So now I also had a rear engine seal leaking.

This means that I had to split the tractor to replace the seal.

Then I pulled off the cylinder head and found a exhaust valve that wasn't sealing.

Then I pulled the pistons and found very worn piston rings and ring grooves on the piston.

Next I found the crankshaft worn and in need of a grinding to 040" for all the bearings.

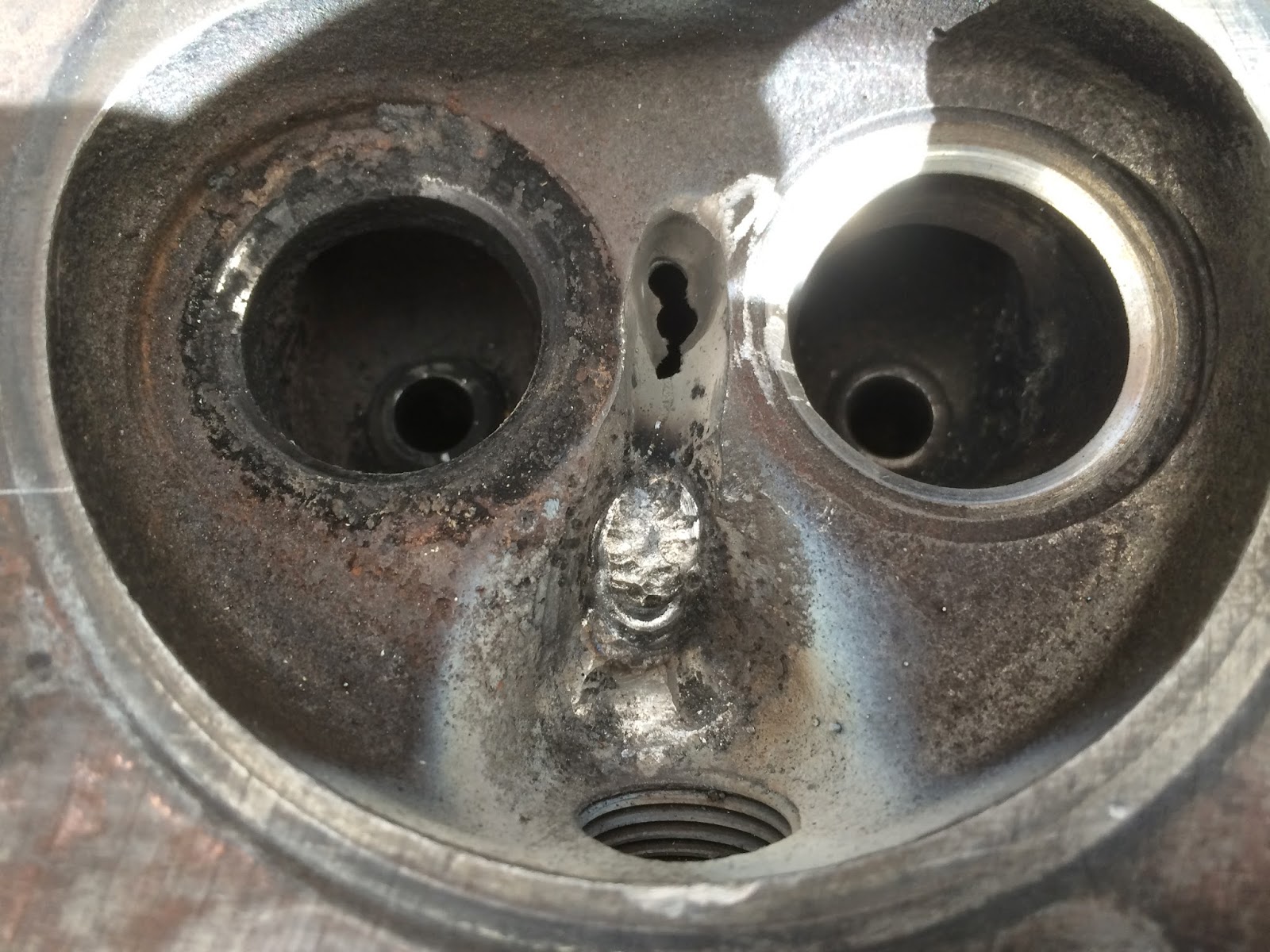

Next, the guys machining the head found that the head was cracked in two places.

I phoned around trying to find a new head but this was difficult as most were found to be cracked.

So I decided to repair the cracks.

So I drilled a hole in both ends of the crack and then grind the cast iron to remove the cracks

Then I started to weld the cracks with a nickle electrode. I welded these cracks very slowly to keep the cast iron from getting too hot and cracking on the weld.

It took all afternoon to repair it, and at no time was it too hot to touch with bare hands.

Finished

Now for the pressure test.